Yerik International

2.5 Hectare( 6.5 Acre ) Land Area and 2 Hecate ( 5 Acres ) Covered Area 3D Solid Works Designing , Solid Modelling with Simulation and Testing Capability. CAD / CAM Die Manufacturing

C.N.C. Centre

Staff Training Centre

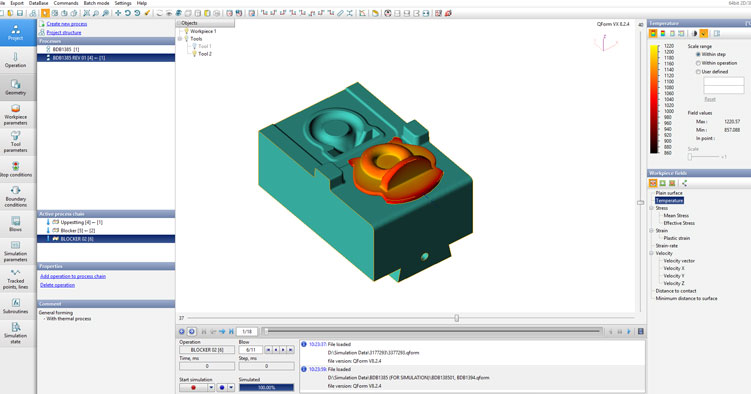

Q Form Forging Simulation Software